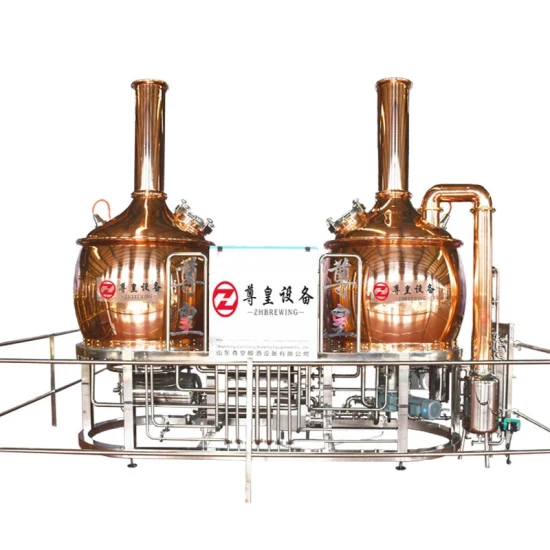

600L Red Copper Brewhouse Micro Brewery Beer Brewing Equipment

Description

Basic Info

| Model NO. | ZH-600L |

| Condition | New |

| Customized | Customized |

| Voltage | 380V |

| Composition | Red Copper |

| Processing Material | Beer |

| Process | Boiling |

| Material | SS304 |

| Tank Thickness | Inner 3mm Outside :2mm |

| Temperature Control | Automatic |

| Heating | Gas Steam Generator |

| Heat Insulation | Rock Wool Th:80-100mm |

| Inner Surface | Pickled and Passivation |

| Welding | Argon Arc TIG 100% |

| Function | Boiling Wort |

| Transport Package | Steel Frame or Wooden Case |

| Specification | as customer request |

| Trademark | Zunhuang |

| Origin | China |

| Production Capacity | 500piece |

Product Description

600L Brewery SpecificationsMash System details:

1. Material: SS304 Inside wall TH=3mm, Red copper outside wall TH=2mm, Insulation: Rock wool, TH=80mm.

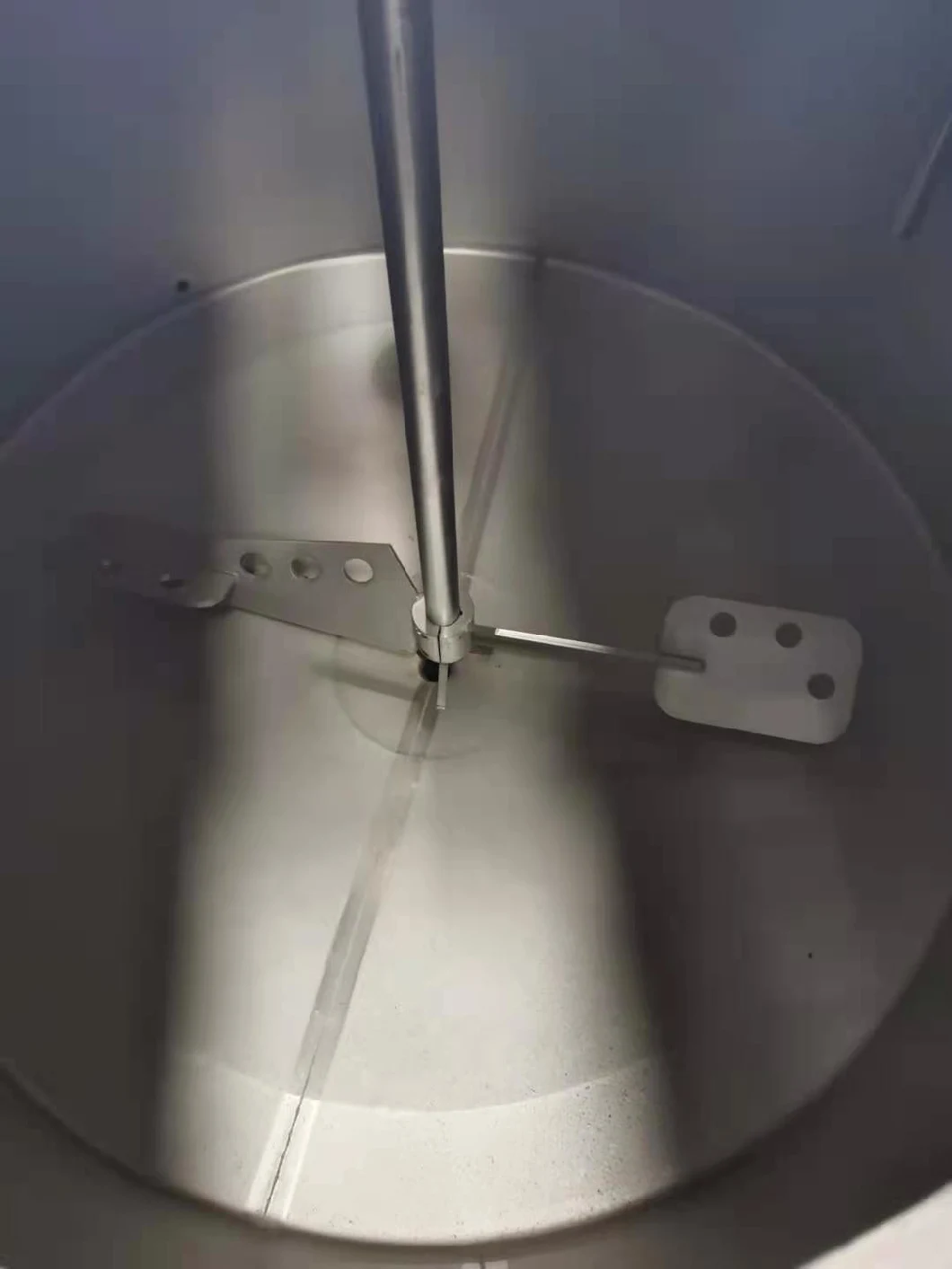

2. The inner surface is pickled and passivated.

3. Heating method: electric heating or steam heating or direct fire.

4. Temperature measurement method: PT100 temperature probe.

5. Cleaning method: Fixed rotate cleaning ball.

6. Top glass manhole.

7. Process: TIG welding, no welding dead, fluid quality assurance.

8. Raker: Horizontal motor stirring, motor power 0.75 KW,

revolving rate 60RPM, high power, low speed to ensure complete worse layer.

Inner surface pickled and passivation:

Mash tun inside with agitator:

Lauter tun inside with raker:

Fermentation tank details:

Fermenter cooling method is cooling dribbling with standard parameters, layout and control mode in domestic. Zunhuang companies design and manufacture cooling dribbling according to 0.4-0.5 meters per cubic meter cooling area. And the fermentation tank adopt two-stage cooling refrigerant control mode at the end of the cone and the tank level 10--15cm down. So such design and cooling method to control the flow of the cooling liquid state in fermentation tank by the size of the two-stage cooling refrigerant flow. It will improve heat transfer efficiency and cooling rate, faster cooling, and reduce cooling costs and high economic efficiency equipment commercial operation.

Other Auxiliary Equipment:

1.Malt crusher

2.CIP Cleaning system

3.Control cabinet

4.Cooling system includes glycol tank and chiller unit

Company:

Shandong Zunhuang Brewing Equipment is a professional beer equipment manufacturer who have 16 years experience in this filed.We are specialized in professional design, manufacture, installation and commissioning of various beer equipments and supporting facilities.Our products include mashing equipment, fermentation equipment, yeast spread cultivation equipment, and We provide equipment with the productivity of 100 liter to 20000 liter per brew.

workshop:Packaging & Shipping

1. Ocean shipment, railway shipment, express delivery.

2. No matter flat pack to save shipping cost, or fill with your merchandise into all assembled displays to ship together, all is up to you.

3. And we have our own department to arrange the shipments. we ship worldwide directly by sea, railway or express.we will provide all documents you need to import.

4. We packed the goods to meet the transport distance, shock, rust, and anti-handling requirements damaged before shipping, to ensure the safe transport of goods to reach the buyer designated location before it is shipped.

Our Services

| a | Free consultation service before, during, and after sales. |

| b | Project planning and design services. |

| c | Free debugging instruction of equipment until everything is functional. |

| d | Management of equipments' long distance shipping from seller's factory to named port or station by buyer. |

| e | Training of equipment maintenance and operating personally. |

| f | New production techniques. |

| g | Provide 36 months complete warrantee for main parts and life-time maintenance service; The seller is responsible for the nature damage of the machinery in the warranty period except for man-made damage; All spare parts and wearing parts are attached with the machinery for free. |

Our Contact