800L Bar Brewpub Beer Fermentation Equipment Beer Brewing Equipment

Description

Basic Info

| Model NO. | 800L |

| Processing Material | Malt, Hop,Yeast,Water |

| Process | Ferment |

| Power | Customized |

| Material | SUS304 or SUS316L |

| Polish | 0.4um |

| Thickness | Inner:3.0mm, Exterior: 2.0mm |

| Testing Pressure | 0.3MPa |

| Insulation Thickness | 80mm |

| Processing Types | Beer |

| Machinery Test Report | Provided |

| Core Components | Gearbox, Motor, Pump, PLC |

| Heating Way | Steam,Direct Fire,Electric |

| Transport Package | Iron Frame & Wooden Crate |

| Specification | 800L |

| Trademark | Cassman |

| Origin | Jinan, China |

| HS Code | 8438400000 |

| Production Capacity | 5000 PCS/Year |

Product Description

800L Bar Brewpub Beer Fermentation Equipment Beer Brewing Equipment

| Name | Complete microbrewery craft beer brewery equipment configuration |

| Grain Miller | Miller with double roller |

| Brewhouse System | Including Mash Tun, Lauter tun, Kettle Tun, and Whirlpool tank; Heating way: Electricity heating, direct fire heating or steam heating; With grain rake, false bottom, spray ball, etc; |

| Fermenter | Fermentation tanks (the capacity is based on the brew batch; the quantity is based on the production); Other accessories are available: 1. L-Pipe; 2. Butterfly Valve; 3. Pressure Gage; 4. Solenoid Valve; 5. Vacuum Valve; 6. Cooling Pipe; 7. Thermal Insulation Pipe;8.Spending valve |

| Glycol cooling unit | Glycol water tank, Coldwater tank, Refrigeration chiller Machine;Sanitary centrifugal pump for glycol water and cold water recycle among tanks and heat exchanger;All pipes, fitting, insulation materials are included. |

| CIP cart | Sterilization Tank, Caustic tank, Hot water tank Thickness is 2mm; Weld slinging band; Valves, accessories supporting; All welding is argon protection single-sided, double-sided forming; Function: Clean in place for tanks |

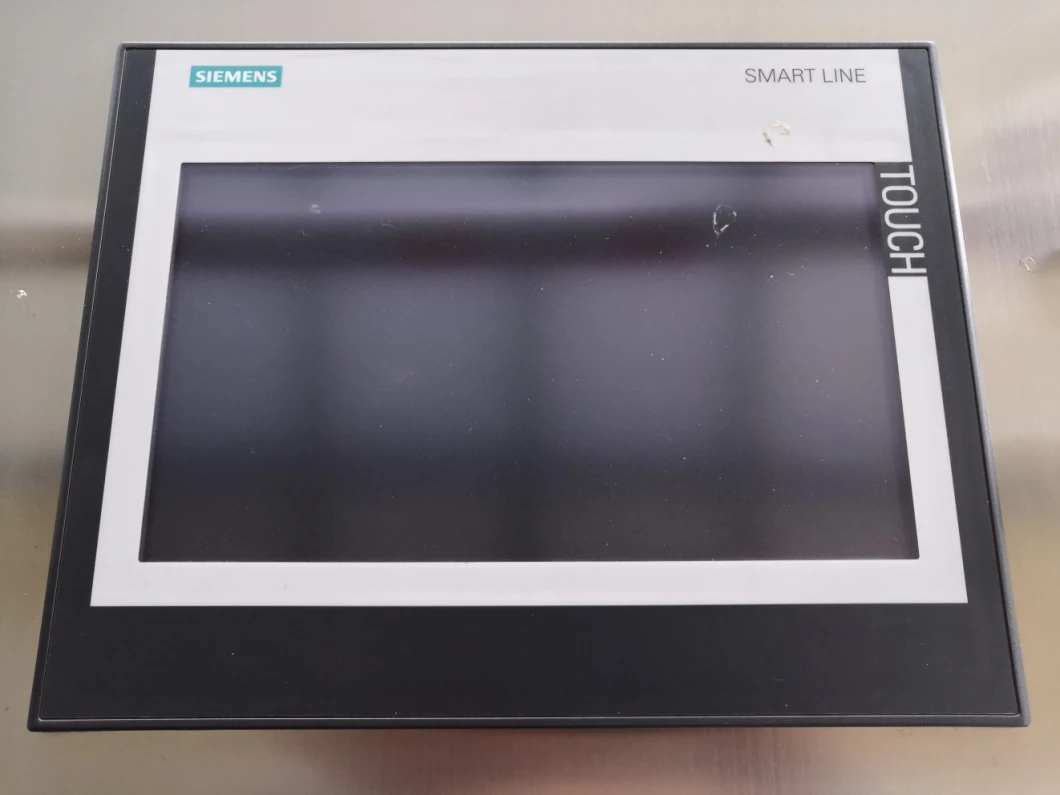

| Control panel | PID semi-auto controller, PLC auto controller, a brand is Siemens, LG for optional. Electric components have CE Certificate.Offer floor type and wall hanging assembling.Control all the tank's temperature, motor, and pump's show on/off. |

| Filter Unit | Kieselguhr filter, Membrane filter; Filtered beer tanks/bright beer tank; In the restaurant, beers are always served as craft beer without filtration. |

| Filling system | Keg filling and washing Machine; Bottle capping and filling Machine. Keg filling and washing Machine; Bottle capping and filling Machine. |

| Other facilities | steam boiler, steam pipe, all the pipes for the brewhouse unit and glycol cooling unit, and so on. |

1. Mill System

Capacity:300kg/h

Description: CE or UL listed Motor, Double roller, distance adjustable, alloy or stainelss steel 304 material.

Optional: Flexible Auger.

2.Brewhouse system:• Steam, Electric or direct fire heating

• Dished top and sloped bottom, 100% TIG welding with pure argon gas shield.

• Working Capacity, +35% head space

• Seperate Hot water tank for option

• Lauter tun with milled false bottom, VFD motor, Sparging and CIP pipe. Level gauge,Side mounted grain outdoor with grain chute,Steam jacket

• Mash tun steam jacket. VFD motor for option.Level gauge

• 6 square meter Plate heat exchanger

• Sanitary Centrifugal pump

• Digital control panel or PID/PLC control system

• SUS 304 tank, pipe, valves, platform and integrated stairs etc.

• Stringent tank leakage test by water and pressured gas.

3. Fermentation tank:

• Working capacity, +25% head space

• SUS 304 material insulated tank.

• 100% TIG welding with pure argon gas.

• 0.3 Mpa test pressure. 0.2 Mpa working pressure.

• Dimple cooling jacket, side and cone of the tank. NPT connection.

• Top relief valve(PVRV), Top dry hopping port.

• Sanitary side manway (top for option).

• Sample valve. Pressure valve, Co2 relief valve, DIN/TC racking arm.

• 60 degree cone.carbonation stone & Level tube for choice, CIP pipe

• 24V solenoid valve.Dial Thermometer. PT100 sensor.

4.Chiller:

5. Control System:

6. All other relative support system such as Steam boiler, burner, Cooling system, Control system, Brite tank, Bottle Filling line, Canning line , Beer keg can be provided.

Cassman Factory

Cassman is the leading Microbrewery equipment supplier in China, our service include the brewery design, equipment manufacture, Installation at site and brewing technology transfer.

We provide complete beer brewing solutions that include: malt handling system, brew house system, beer fermenting/storage system, cooling system, cleaning system, control system, package line.

Established in 2010, Cassman brewing equipment has been exported to more than 20 countries, which include USA, Canada, Australia, Japan, UK, France, Germany, Denmark etc.

Project Reference

Certification

Our Contact