Flexible Brick Box Carton Food Milk Juice Drink Bottle Wine Beer Aseptic Filling Beverage Bottling Sealing Pack Tetrapack Packing Packaging Machine

Description

Basic Info

| Model NO. | Customized |

| Automatic Grade | Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Multi-Room Feeding |

| Dosing Device | Capacity Cup |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Box |

| Packaging Material | Plastic |

| Machinery Capacity | 2000bph |

| Packing Material | Brick, Bottle, Carton |

| Application | Beverage, Food, Powder, Juice, Drink, Liquid, Mik |

| Packaging Type | Bags, Bottles, Cans, Cartons, Pouch, Stand-up Pouc |

| Packaging Capacity | 2400 Boxes Per Hour |

| Energy Consumption | up to 70% |

| Sealing Function | Yes |

| Bottling | Suppport |

| Filling | Support |

| Aseptic | Certificated |

| High Efficiency | Yes |

| Environmentally Friendly | Yes |

| Usage | Beverage Industry |

| Quality | Global Verified |

| Machinery Test Report | Provided |

| Transport Package | Standard |

| Specification | Customized |

| Trademark | WONSTEN |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 500 PCS Per Year |

Packaging & Delivery

Package size per unit product 200.00cm * 100.00cm * 1200.00cm Gross weight per unit product 750.000kgProduct Description

| Automatic Flexible Brick Slim Box Carton Food Milk Juice Drink Bottle Aseptic Filling Beverage Bottling Sealing Pack Tetrapack Packing Packaging Machine |

Aseptic Packaging

Committed to sustainability and concerned about our ecosystem's carbon footprint, we contribute to the preservation of the environment by installing in our machines the latest technology to reduce energy consumption and film waste, and actively engage in Recyclable packaging solutions.Aseptic Packaging Reduces Energy Consumption.Aseptic technology expands potential for fresh products by freeing you from the cost, logistics, and energy restraints of cold chain. Provide preservative-free products that stay fresh up to 12 months on the shelf-no refrigeration needed. By Wonsten aseptic packaging technology, you can reduce your reliance on cold chain logistics and decrease your energy consumption by up to 70%.

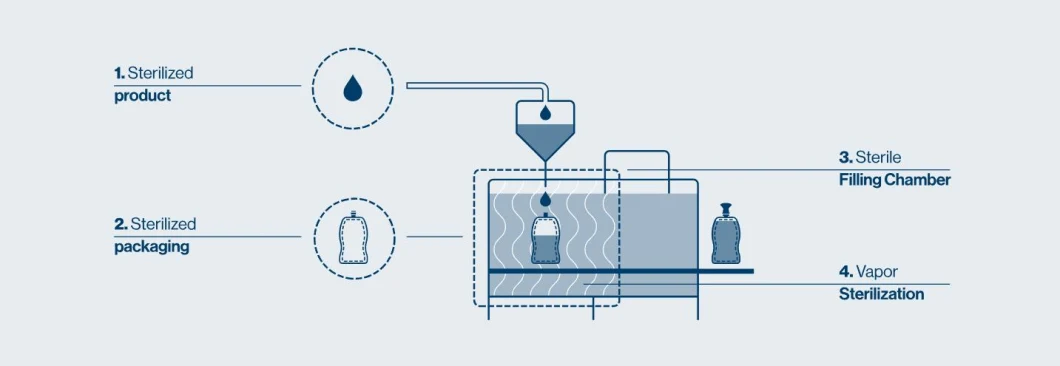

Detailed PhotosProduct ParametersThe Aseptic process for pouches.Pre-sterilized pouches on rails are indexed in the tunnel. This tunnel contains vapor hydrogen peroxide.

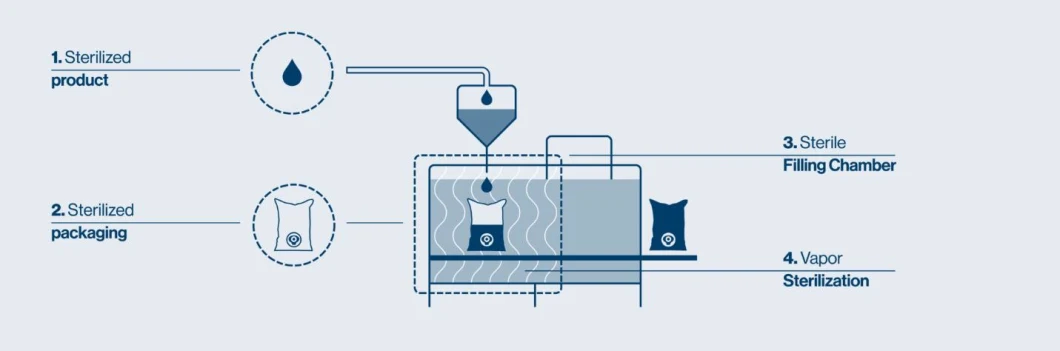

The Aseptic process for bag-in-box.

Pre-sterilized bags are indexed in the tunnel. This tunnel contains vapor hydrogen peroxide.

Bottling

Wonsten offers complete aseptic packaging lines for bags or sachets, designed under parameters of automation, innovation and food safety; which guarantee greater productive efficiency.

Process

Wonsten technological processing solutions have been designed for the aseptic treatment of products such as beverages, ice creams, juices, milk and their derivatives, guaranteeing savings and increasing their efficiency.

End of life

Through advanced technological tools in engineering, Wonsten specialists design systems that allow complete end-of-line automation, optimizing production processes and guaranteeing productive efficiency.

Technical support

Wonsten has extensive coverage in after-sales service, training and technical attention of its products, ensuring the maximum performance of Wonsten technological equipment 24 hours a day and 7 days a week.

Operational efficiency

Wonsten designs strategic plans that allow food producers to implement best practices for quality assurance in processes, assets, products and human resources; guaranteeing greater operational excellence and productive efficiency.

Prev: Industrial 2000L Beer Brewery Equipment for Beer Brewing Fermentation System

Next: High Quality Complete Carbonated Soda Water Production Filling Packing Line

Our Contact